In the biological context, a mosquito is a blood-sucking insect that has, for many millennia, inflicted much misery upon humankind, and in the case of the Anopheles (malarial) mosquito, even outright mass death. In the military aviation context, “Mosquito” refers to the de Havilland Mosquito, a sleek, speedy British warplane – made almost entirely of wood – that enabled the Royal Air Force (RAF) to inflict much misery, death, and destruction upon the Axis powers during World War II.

Meanwhile, on the Axis side of the WWII aviation ledger, the name Focke-Wulf conjures up thoughts of deadly warbirds such as the Fw 190 Würger (“Shrike;” or as Allied bomber crews called her, the “Butcher Bird”) fighter plane and the Fw 200 Condor.

So then, a warplane bearing both the monikers Focke-Wulf and “Moskito” should’ve made for an absolutely deadly best, Jawohl? Er, actually, not so much, and a major reason for the failure of the Fw 154 Moskito – which had been intended as a night fighter – was the dearth of a very basic ingredient needed to literally hold the plane together.

The missing key ingredient

The title of the YouTube video sums it up: “Defeated By…A Lack Of Glue?: Focke-Wulf Ta 154 Moskito.”

That’s right, folks, glue!!

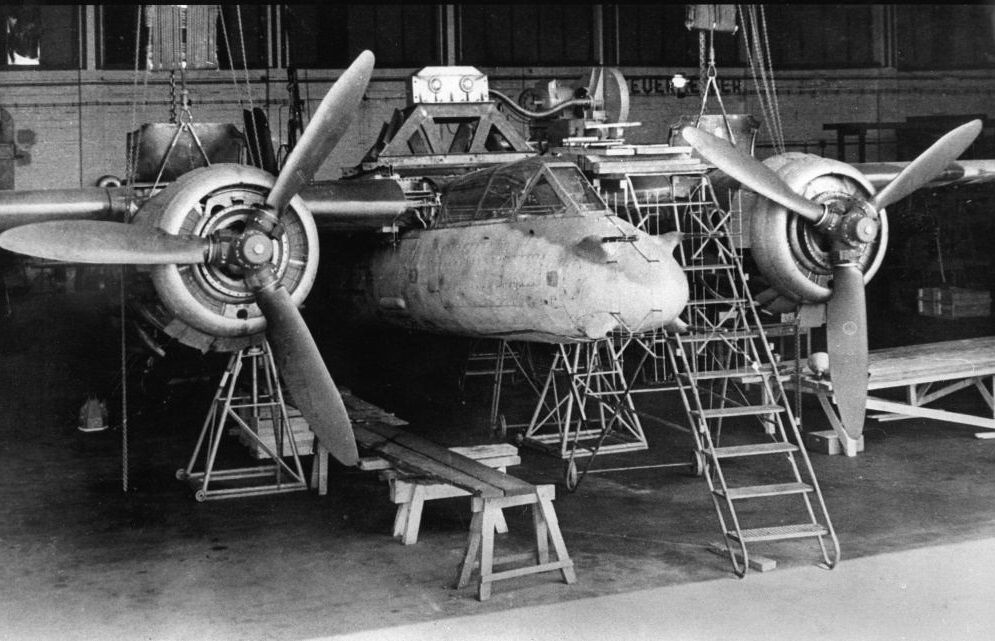

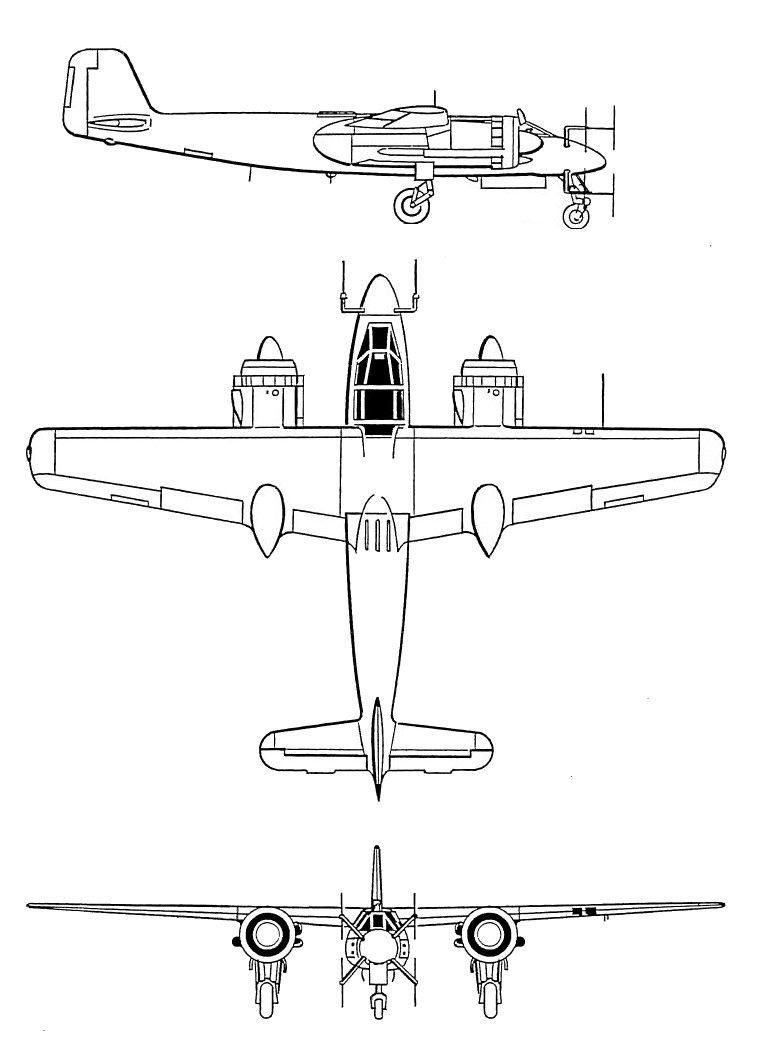

To elaborate further (and to make a long story short, for the benefit of any of our readers who are in too big a hurry to watch the entire 24:52 video at one sitting), the German Moskito attempted to plagiarize, er, emulate the British Mosquito not just in name, but in terms of mostly wood construction. Indeed, the Ta-154’s only large-scale use of metal was in the then-state-of-the-art pressurized cockpit.

However, the plywood that went into the construction of the German namesake of the bloodsucking flying bug was bonded using a proprietary waterproof phenolic resin adhesive called Tego-Film, made in only one factory in Germany, located in the North Rhine-Westphalia. And that one measly factory was destroyed in a February 1943 bombing raid carried about by…oh, how’s this for irony: RAF Mosquitos! (Would that make the British warbirds [war bugs? bug-birds?] guilty of a mechanical form of cannibalism?)

“Phenolic” derives from the word “phenol,” which Merriam-Webster defines as “a corrosive poisonous crystalline acidic compound C6H5OH present in the tars of coal and wood that in dilute solution is used as a disinfectant.”

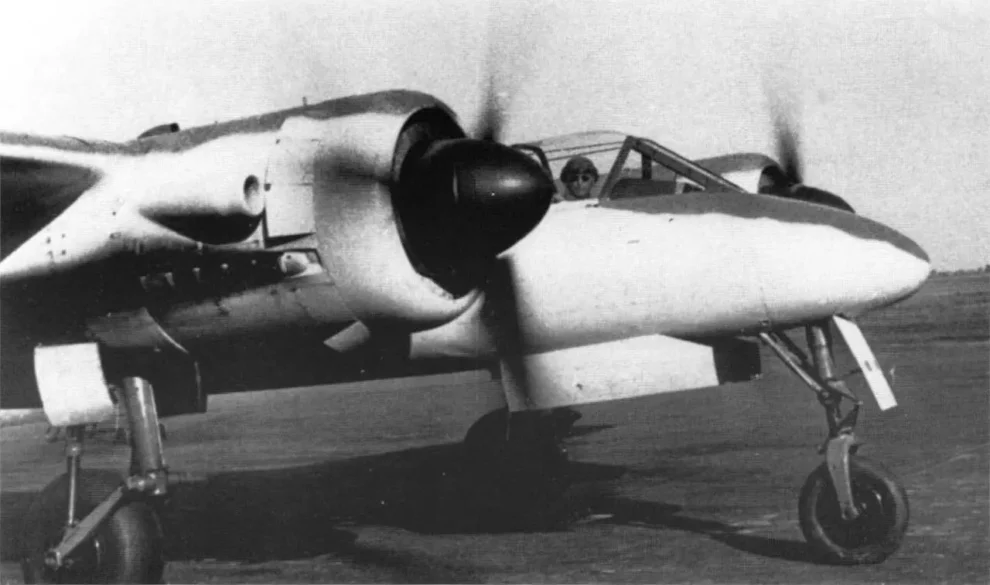

Frankly, my first thought when I saw the above photo was that the German warbird didn’t so much resemble the Brit plane but looked more like a Heinkel He 162 Volksjäger (“People’s Fighter;” AKA Spatz [“Sparrow”] AKA “Salamander”) jet fighter mated with a Messerschmitt Bf 110 twin-engine prop fighter, with the Heinkel’s jet engine genetics turning out to be recessive in the resulting offspring.

In any event, “Adapt, Improvise, Overcome,” as the popular military saying goes, and the Nazi German manufacturing gurus certainly attempted to apply this principle in an effort to keep the Ta 154 viable. The makeshift solution was to substitute another adhesive, this one produced by Dynamit Nobel AG from Leverkusen, but the new adhesive was only half as powerful as the Tego-Film. This negative strength differential would prove fatal, as noted Lorenz Bärmann of the Warbirds Resource Group:

“On July 1944 two Ta 154 A-1’s completed using the Dynamit glue took off for testing. The second aeroplane crashed when its wings desintegrated: the glue ate into the wooden structure! Due to these problems with the wooden parts, and following further crashes of two other aeroplanes, Tank halted series production on 14 August 1944. RLM halted the entire project in September 1944, a little more than six months after its air worthiness certificate. In Posen, eight Ta 154 A-1s were built before the end of the program.”

But, that wasn’t the only problem.

As if lack of a basic building block commodity like glue wasn’t bad enough, Quora poster Alan Dicey (self-described as “Former engineer, Avionics and IT,” with a Bachelor of Science degree in Applied Physics and Electronics from Durham University) adds these insights in response to the question “Why didn’t the Germans just copy the Mosquito in WW2?”:

“I see the red flag ‘Why didn’t they just…’ phrase rearing its unfortunate head again…The Germans did not have Rolls-Royce Merlin engines, high-octane fuel or access to the resources of Ecuador, Canada and the US. Nor did they have Geoffrey de Havilland“….The nearest the Wehrmacht got to a Mosquito-clone was the Focke-Wulf Ta 154 Moskito, a night fighter expected to match the Mosquito in performance…

“The Moskito did not use the pioneering light and strong ply-balsa-ply sandwich of the Mosquito – Germany had no access to Ecuadorean balsa wood. Canadian birch ply and spruce for spars was also beyond their reach.”

What might’ve been: Ta 154 Moskito early history and specifications

The Moskito, which was designed by Kurt Tank (who also created the aforementioned Fw 190 and Fw 200), made her maiden flight on July 1, 1943 (five months after the destruction of that aforementioned oh-so-crucial factory). As far as I can ascertain, none of the eight that were actually built still survive today,

| Crew | 2 |

| Fuselage Length | 40 ft 10 in (12.45 m) |

| Wingspan | 52 ft 6 in (16 m) |

| Height | 11 ft 6 in (3.5 m) |

| Empty Weight | 14,551 lb (6,600 kg) |

| Max Takeoff Weight | 21,054 lb (9,550 kg) |

| Max Airspeed | 400 mph (650 km/h; 350 kn) at 23,260 ft (7,090 m) 332 mph (534 km/h; 288 kn) at sea level |

| Range | 848 mi (1,365 km; 737 nmi) at 23,000 ft (7,000 m) |

| Service Ceiling | 35,800 ft (10,900 m) |

| Armament | Two 20 mm (0.787 in) MG 151/20 cannon with 200 rounds per gun; two 30 mm (1.181 in) nose-mounted MK 108 cannon with 110 rounds per gun; (Ta 154C varaint only) + 2 × fuselage-mounted Schräge Musik 30 mm (1.181 in) MK 108 cannon. |

Source: Simple Flying